Background

Hall Earth Moving

Tasmania

Hall Earth Moving (HEM) is a privately owned and Tasmanian-based company, operating in the construction industry for over 30 years.

They have a diverse spectrum of works from minor to bulk earthworks, civil road construction, and hardstand works, with a specialised emphasis on embankment dam construction. The company maintains a longstanding commitment to safety by engendering a culture of safe work practices and strong occupational health and safety systems for every project.

Challenge

Hall Earth Moving was constructing the Hellyer Gold Mine Tailings Storage Facility, located approximately 1 km west of the Hellyer mill, as part of Nq Minerals’ environmental clean-up initiative and site rehabilitation.

The project involved 500,000m3 of fill placement for a nine-metre dam raising, plus the face liner works. The face liner is a bituminous membrane. The liner material arrived in four and five and a half metre-wide rolls and was deployed from the dam’s crest, and subsequently, the seams were welded together.

The Project

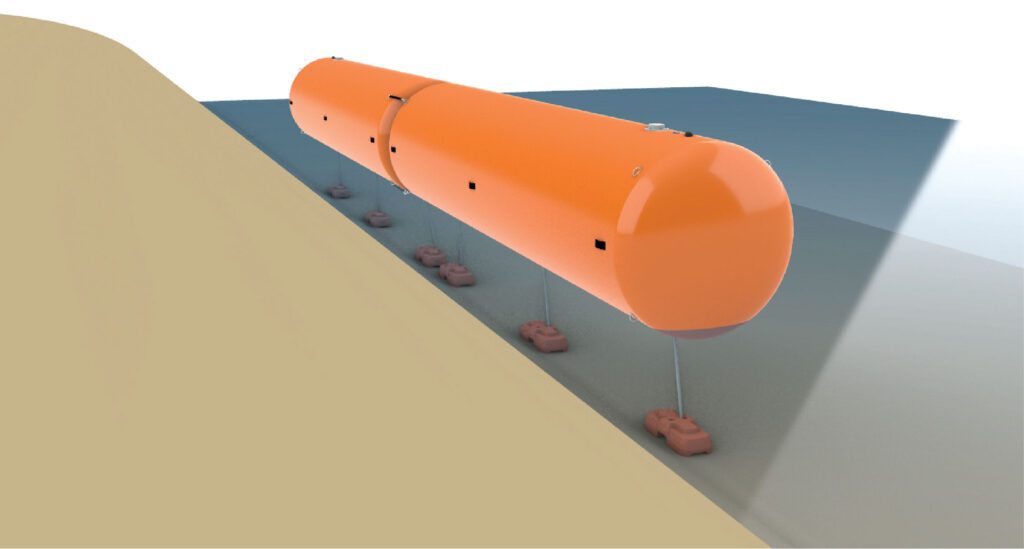

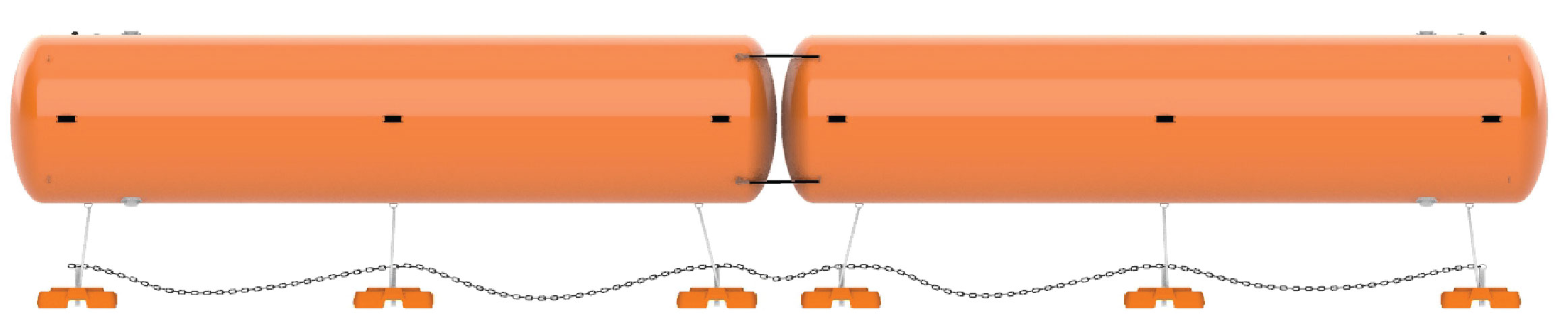

Hall Earth Moving (HEM) contacted Giant Inflatables Industrial (GII) to manufacture an inflatable aquatic safety barrier to protect men deploying and welding the liner against entry into the tailings water during construction.

HEM required fifty linear metres of the barrier, enabling the deployment of five or six roll widths of the liner membrane before welding with a ten-metre extension on either side of the work area for additional safety.

GII manufactured the inflatable aquatic man safety barrier in the form of a cylindrical tube 1.2m in diameter made in nominal five-metre lengths to create segments to suit the width of the liner rolls. Each component was tethered at the ends through a set of eyelets and contained water for ballast and maintained a low inflation pressure, and was anchored in the water for stability.

To compensate for the PH levels of the tailing water, which fluctuates between six and eleven, GII paid particular attention to the fabrics used in the manufacturing process to mitigate the danger of premature deterioration of the barrier.

Results

The Aquatic Man Safety Barrier was delivered in mid-December and deployed in January 2023 for the duration of the three-month project.

A closer look

Your partner

in industrial inflatables

Need information off-line?

Download a PDF for your records in two steps.

Inflatable Hopper Plug

An inflatable hopper plug “or carrot” is used to facilitate the flow of sugar during shipping events.

Inflatable Void Former

An inflatable void former has substantially reduced the semi-mobile mining unit plant’s ongoing labour and operational costs.

Need more information?

Contact us. We would love to be apart of your solution.