Back Ground

Duratec Australia

Australia

Duratec Australia is a leading industrial contractor specializing in protective coatings, remediation, and maintenance services. The company focuses on delivering innovative solutions for asset protection and durability across various industries, including mining, oil and gas, water, and infrastructure. Duratec excels in providing corrosion prevention, concrete repair, and industrial painting services. With a commitment to safety and quality, they leverage their expertise to enhance the longevity and performance of critical assets.

Challenge

Inflatable forms are the solution

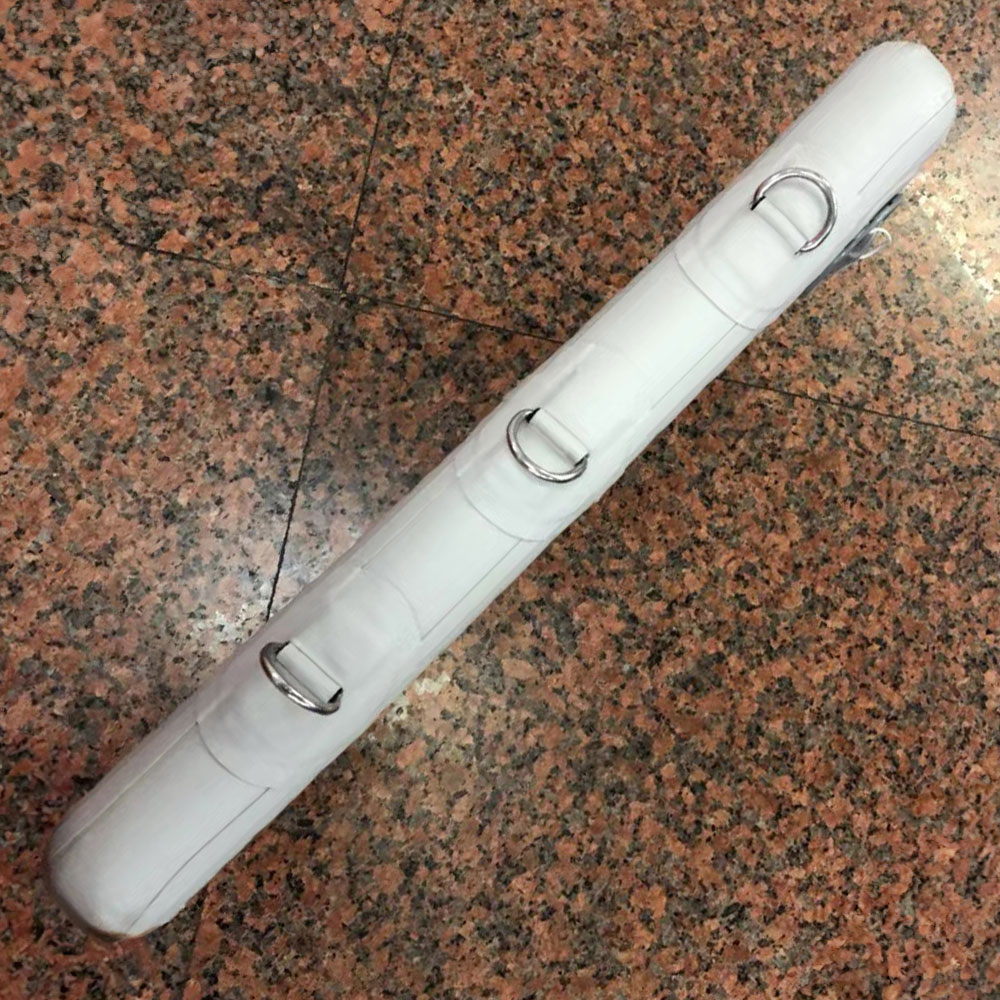

Inflatable forms have many advantages over traditional forms and shuttering systems and were the perfect fit for this mining remedial project.

Inflatable forms are lightweight and easier transport set up and store when not in use, compared to traditional forms and shuttering.

The flexible nature of inflatable forms makes it easy to install in inconvenient or awkward spaces.

The porous, malleable nature of the rubber surface of the inflatable form creates a perfect seal against other surfaces. This is especially true when the surface is uneven.

Inflatable forms can be created in virtually any form and the drop stitch matrix web construction.

Results