Background

Gladstone Power Station

Gladstone, Queensland

NRG Gladstone Power Station is a world-class facility providing safe, reliable, low-cost electricity. It was built in 1976 by the Queensland Government. After 40 years of operation, it is still Queensland’s most prominent single coal red power station. The station continues capital work to ensure environmental improvements and reduce emissions.

NRG Gladstone Power Station was looking for an inflatable duct barrier to seal off an exhaust gas duct from incidental gas flows in a neighbouring generator unit. The isolation duct cushion ensured that if there were any faults with the stack damper, the inflatable duct barrier would prevent downdrafts.

Specialized Solution

The concept of an inflatable duct barrier would have to be translated to the Occupational Health and Safety Board (OHS) to meet their rigorous standards regarding installation, operation and removal.

The exhaust duct was subject to temperatures of up to 120°C, requiring extra-robust, heat-resistant materials adding considerable volume to the deflated barrier.

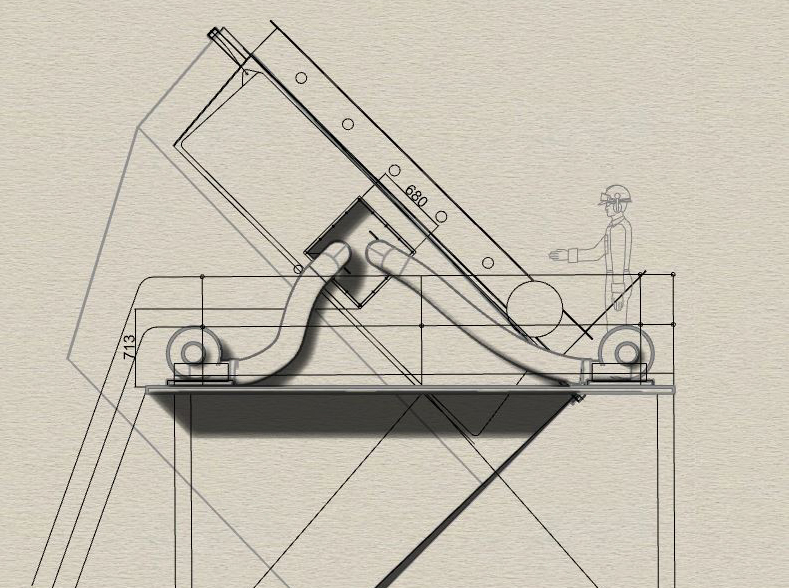

Even when deflated and folded, the voluminous duct barriers must be inserted through an entry point of only 680mm x 680mm.

The overall weight of the deflated duct barrier had to be light enough for a man to manage, carry and push through the restricted entry point.

The inflated duct barriers would need to be securely tethered to the exhaust duct to create a complete seal, guaranteeing the safety of the workers and ensuring the satisfaction of the requirements laid out by the OHS.

Results

After thoroughly inspecting the Gladstone Power Plant, the engineering team at Giant Inflatables created and presented a clear and concise solution to the stakeholders. The company’s OHS officers approved the detailed designs and plan of execution.

The inflatable duct barrier’s final design resulted from over 20 years of experience in inflatable engineering and a thorough knowledge of industrial fabrics. The 2343mm x 3943mm structure was designed and fabricated, practising a strategic balance between fabric durability, overall weight and volume, and manageability.

The GII team took an innovative approach to fasten the inflatable duct barrier. The complexity of the installation process required that all the fastening hardware be installed before the duct cushions were inflated. Then, once the duct cushions were inflated, the necessary tethers were threaded and fastened from outside the duct.

The custom-designed inflatable duct barrier was efficiently installed without incident and successfully sealed off the vent, preventing downdrafts caused by potential faults with the stack damper. The duct barrier installation didn’t require removing large panels of the ventilation system or using labour-intensive scaffolding, resulting in substantial cost savings while providing a safe environment for Gladstones workers.

Your partner

in industrial inflatables

Need information off-line?

Download a PDF for your records in two steps.

Inflatable Hopper Plug

An inflatable hopper plug “or carrot” is used to facilitate the flow of sugar during shipping events.

Inflatable Void Former

An inflatable void former has substantially reduced the semi-mobile mining unit plant’s ongoing labour and operational costs.

Need more information?

Contact us. We would love to be apart of your solution.