Back Ground

Wolfram

Mittersill, Austria

Wolfram Bergbau und Hütten AG (WBH) operates one of the world’s largest tungsten mines, located in Mittersill, Austria, within the Hohe Tauern National Park. The operation began as an open-pit mine in the late 1970s and later transitioned to an underground operation.

After decades of continuous operation, the mine’s infrastructure is ageing quickly. Much of the equipment, initially designed for a ten-year service life, is now several decades old, creating a need for basic infrastructure repairs.

A large portion of the maintenance and repairs focused on the steel structures in the bunkers located below the two hoppers that empty the main chute. The main chute was cut out of the mountain and lacks a concrete or reinforced casing. The nature of the maintenance work could expose workers to falling rocks, gravel, and other debris from inside the main chute. To minimise the risk of falling debris, the engineers contacted Giant Inflatables Industrial (GII) for an inflatable debris fall protection solution.

Challenges and Design

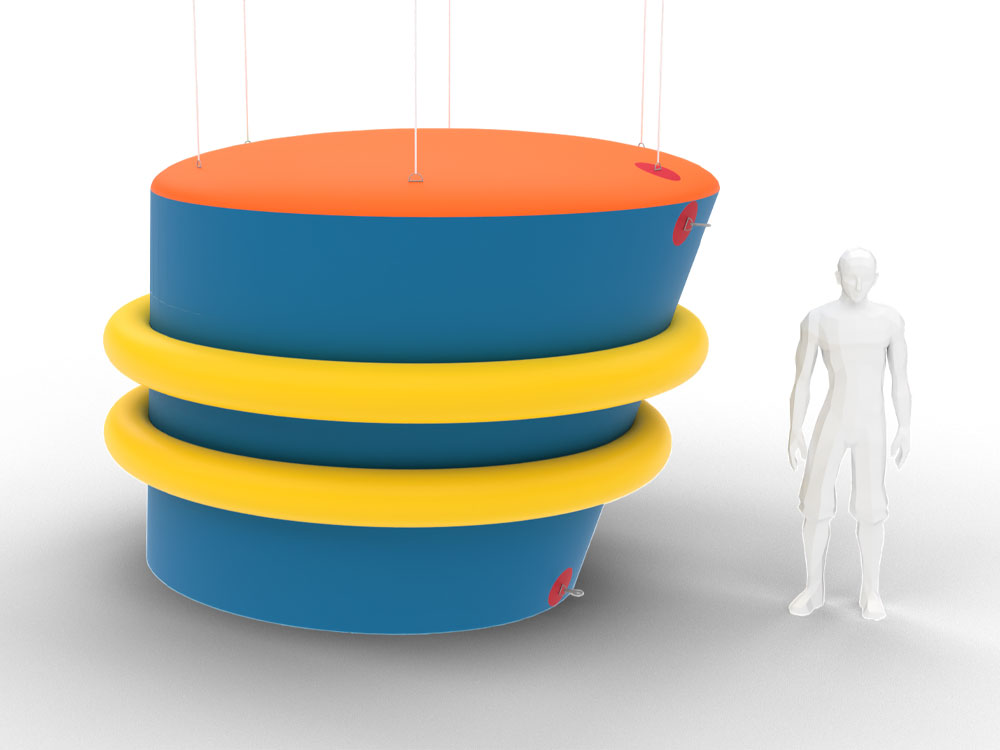

The main chute is 16 metres wide, 7 metres deep and 30 metres high. Access to the chute was limited to under two metres, so creating an isolation barrier that covered the entire width of the chute would have been too cumbersome to manage as a single unit.

The GII design team and the mine’s engineers collaborated effectively, deciding on two specifically designed inflatable isolation cushions to fit the uniquely shaped shafts. These cushions were strategically placed to lodge and seal off each of the two hoppers, well above the working environment, ensuring maximum safety.

The two inflatable debris fall protection were designed with an abundance of security redundancies to ensure the security of the workers. The top of the inflatable debris fall protection was covered with a high-strength, 1200g high-impact absorption sheet. The interior construction included four independent baffles to ensure that if falling debris damages one layer, it would be blocked by the next. Each plug had two additional void filler rings around the circumference to /ensure that the shaft was completely and securely sealed. Heavyweight, colour-coded d-rings allowed the maintenance teams to lower the isolation barriers in the exact position required. Fire-retardant material was used throughout the structures, as they would be in proximity to welding operations.

As the main chute was 30 metres deep, a constant air inflatable was chosen with a built-in inflation system.

The Results

The two inflatable debris fall protection, designed and shipped from Australia to Mittersill, Austria, performed exactly as intended. Positive feedback from the engineers and project managers during the GII debriefing procedure confirmed the project’s success and their satisfaction with the entire process, from initial design through delivery and installation.

A closer look

Your partner

in industrial inflatables

Need information off-line?

Download a PDF for your records in two steps.

Inflatable Void Former

An inflatable void former has substantially reduced the semi-mobile mining unit plant’s ongoing labour and operational costs.

Inflatable Hopper Plug

An inflatable hopper plug “or carrot” is used to facilitate the flow of sugar during shipping events.

Need more information?

Contact us. We would love to be apart of your solution.