Background

Origin Energy is an Australian integrated energy company exploring for and producing natural gas, generating power through wind and solar and supplying and selling electricity, natural gas, LPG and solar. Origin has multiple energy plants and numerous turbine generators to provide energy.

Challenge

All power-generating companies must service and refurbish the power turbines’ efficiency.

This cleaning process requires a complete disassembly process. Once disassembled, the individual parts are cleaned using a high-powered abrasive blasting process. Subsequently, the maintenance crew tests and reassembles the turbines.

The abrasive blasting process, testing and reassembly must occur in an encapsulated space in a contained environment.

The size requirements are the primary concern, as the crew transports the turbines in their entirety on a flatbed truck. Then, the company builds the structure around the turbine before maintenance begins. As a result, the costs associated with labour and time of using the traditional scaffolding and cover methods are cumbersome. This process generally takes 2 to 3 days by the time the site receives the necessary Occupational Health and Safety (OH&S) certificates.

Image of typical power turbine for demonstration purposes

Specialized Solution

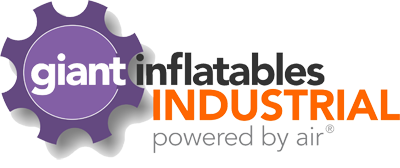

Giant Inflatables designed a temporary abrasive blasting shelter measuring 8m x 12m x 7 meters high. They constructed the 672 cubic metre, self-supported inflated shelter specifically for abrasive blasting. It has extra internal skins to minimize blasting noises and screens to catch blasting media.

Once inflated, a crane can lift the temporary abrasive blasting shelter over the turbine, eliminating the need for scaffolding structures. Moreover, once the maintenance work is complete, a minimal crew can quickly deflate the shelter and place it on a single pallet. The temporary blasting shelter is always ready to be deployed to multiple locations throughout Australia.

Results

The temporary abrasive blasting shelter saves Origin time and money from two perspectives. They have substantially reduced the person-hours necessary to prepare for abrasive blasting by not using the scaffolding and cover method. Secondly, they reduced the maintenance time by three days, putting the power turbine back to work and generating power sooner. Furthermore, the use of the shelter substantially reduced safety issues raised by the OH&S, creating a safer environment for the workers.

The temporary abrasive blasting shelter will provide years of efficient use for all of Origins’ energy plants across Australia.

A closer look

Origin has substantially reduced the person-hours necessary to prepare for abrasive blasting by not using the scaffolding and cover method.

Your partner

in industrial inflatables

Need information off-line?

Download a PDF for your records in two steps.

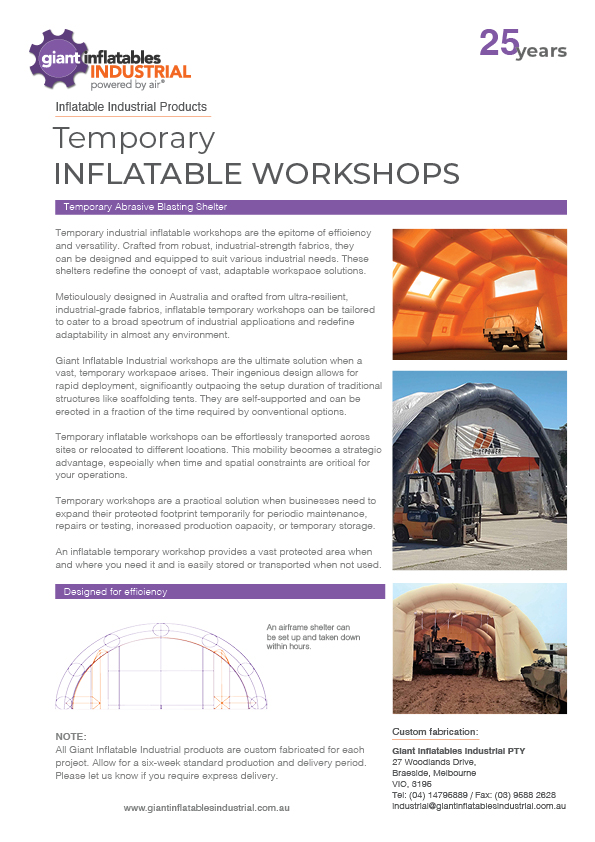

Inflatable Temporary Workshop for Military Use

Cubic Defence approached Giant Inflatables Industrial to manufacture an inflatable temporary workshop to fit equipment to military personnel and vehicles in all weather conditions.

Need more information?

Contact us. We would love to be apart of your solution.