Back Ground

CS Energy | Callide Power Station

Biloela, Central Queensland

CS Energy is a proudly Queensland-owned and based energy company that provides power to some of the state’s biggest industries and employers. They supply electricity from coal-fired thermal facilities and are ambitiously investing in new energy assets such as renewable hydrogen, solar and wind farms, and battery storage.

One of their power facilities is the Callide power station, located at Biloela, Central Queensland.

Callide Power Station receives up to 5.8 million tonnes of black coal annually, has a capacity of 700 megawatts and comprises two 350 MW Hitachi generating units.

Fly ash emissions are controlled at Callide using electrostatic precipitator technology, a commonly used technology worldwide today. Electrostatic Precipitators remove the particulates from the flue gas or boiler exhaust.

CS Energy must regularly perform maintenance, cleaning and repairs to the precipitators and ventilation systems to ensure emissions stay at acceptable levels and the system produces energy efficiently.

Challenge

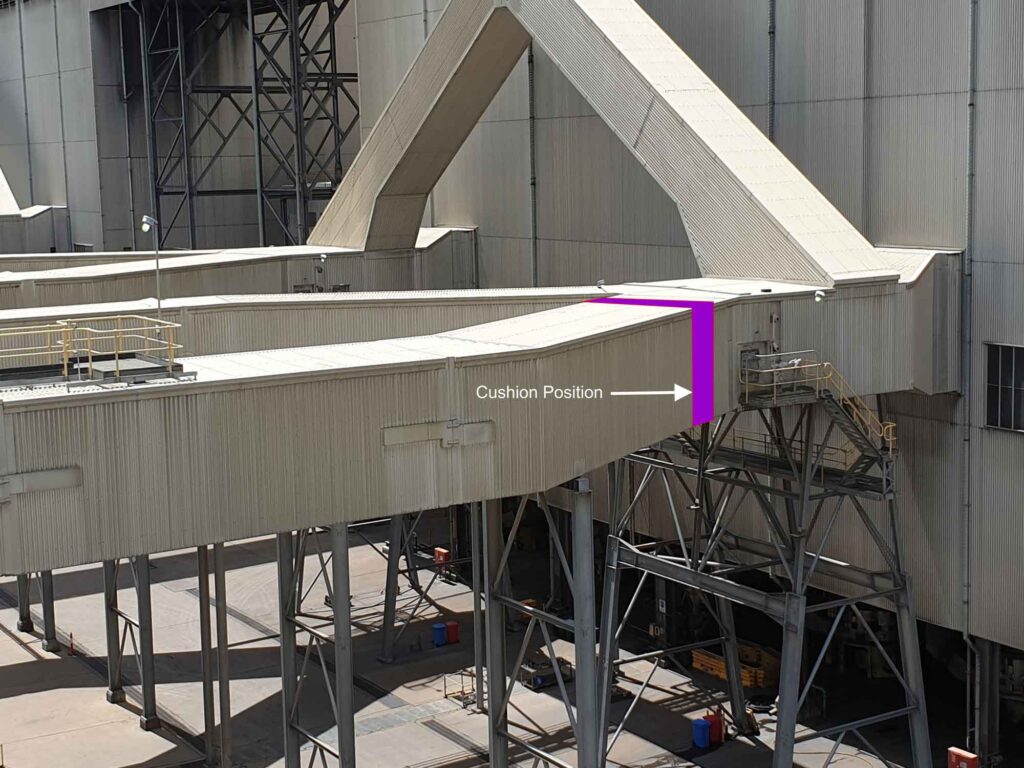

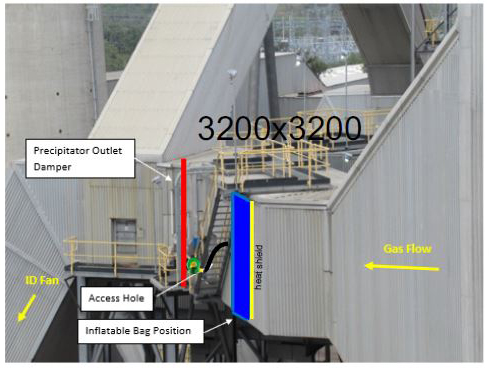

Workers must enter and work in a confined space to carry out the necessary maintenance. Employee safety is paramount at CS Energy, and to achieve an acceptable safety rating, the CS Management Team was invested in isolating the working area using the double block and bleed method.

In this scenario, the double block and bleed method blocks both sides of the working area, producing a vent or “bleed” between the barriers. The bleed or vent area is where the opening to the workspace is located.

CS Energy called the Giant Inflatables Industrial (GII) engineers to design and fabricate inflatable duct cushions to serve as the block and bleed system.

Specifications for the

Double Block and Bleed System

Inlet – 3020mm x 3020mm

Outlet – 3200mm x 3200mm

Resistance ratings:

Back-pressure at 1.7Kpa

Anchor rating at 5.2Kpa in total

Solution

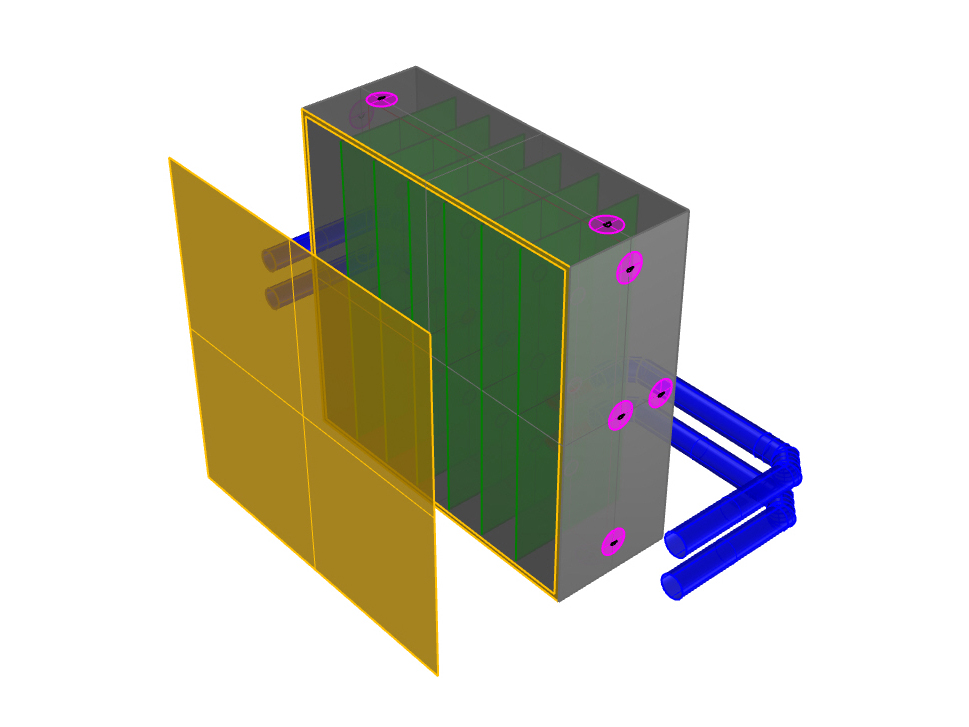

The cushions were engineered using a combination of experienced, tried and tested designs from GII’s past power plant projects while integrating innovative materials to deal with heat-related and highly abrasive and corrosive material issues.

GII created a detachable heat protection shield for the structure to mitigate potential danger to the workers and damage to the blocking cushions from extreme blast temperatures. The heat protection shield is foldable and attaches to the system with velcro, allowing it to enter the workspace through the ventilation and workplace entry point.

GII fabricated the cushions with the six ties and anchorage points reinforced with redundancy to ensure the structure would remain in place despite the possible high wind velocity.

To install the double block and bleed system in place, both cushions, in a deflated state, were folded strategically and brought through the small opening in the vent. The folded heat shields followed, and the workers inflated the system using a deployment dance choreographed and demonstrated by the Giant Inflatables team using a fold-out modelling system.

Results

The resulting industrial duct cushion ensemble achieved its objectives as a sealing duct plug. It exceeded the Occupational Health and Safety Board (OHS) requirements of a double block and bleed system.

“I have now had the pleasure of working with David Abramowitch and the Giant Inflatable Industrial team for two projects on two different power stations in Queensland. Both projects involved developing ways to seal large flue gas ducts for safer work conditions in confined spaces. Large inflatable isolation plugs were designed and manufactured with appropriate materials, inserted and inflated the vents to provide the seal. Using inflatables avoided significant alternative mechanical engineering and ductwork modifications and associated costs. David and his team’s innovation and collaboration were vital to these safety and access improvements.”

Bob Saunders

MANAGER

Callide C Power Station

A closer look

Your partner

in industrial inflatables

Need information off-line?

Download a PDF for your records in two steps.

Inflatable Isolation Duct Cushion

The isolation duct cushion ensured that if there were any faults with the stack damper, the inflatable duct barrier would prevent downdrafts.

Need more information?

Contact us. We would love to be apart of your solution.