Back Ground

High Impact Solutions

Roxby Downs, Australia

High Impact Solutions Group is a leading Australian specialist serving the resources, energy, and infrastructure sectors. They deliver expert industrial services, including complex demolition, remediation, and civil construction. Known for managing high-risk environments, they utilise advanced technology and engineering to ensure safety and operational efficiency in large-scale projects.

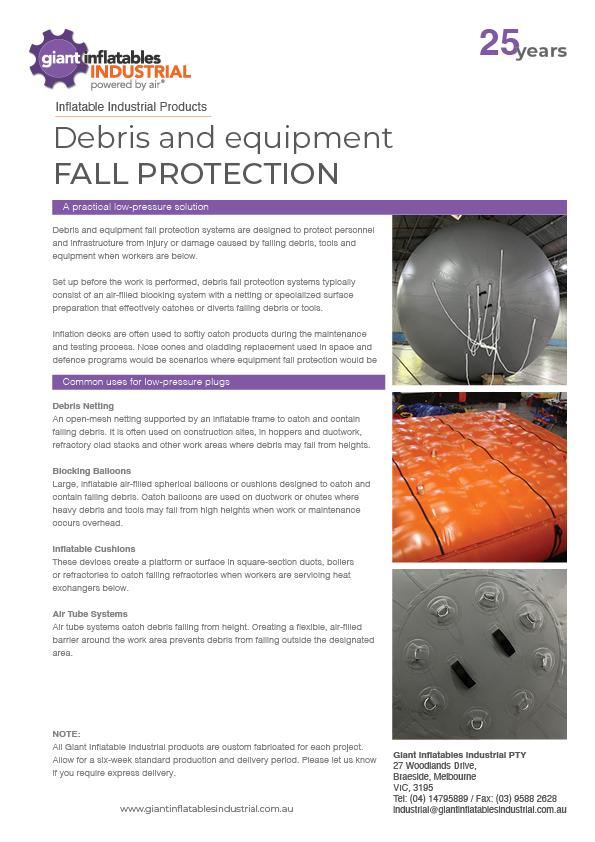

The Olympic Dam copper and uranium mine sits 560 km north of Adelaide near Roxby Downs. High Impact Solutions required a specialised engineering solution to safely disassemble a large industrial stack.

The team approached Giant Inflatables Industrial to manufacture a custom Debris Fall Protection Plug.

Challenge

Demolishing a vertical stack presents significant safety risks. You must control fallout to protect workers and equipment located at the base. The structure also requires stabilisation while cranes detach specific sections.

Uncontrolled movement or falling material could cause severe accidents.

The Debris Fall Protection Plug needed to be positioned and inflated securely from the top of the stack, which meant it needed to be lightweight for handling yet strong enough to hold heavy waste material.

It also needed to withstand the friction and pressure of the dismantling process. Standard off-the-shelf products could not meet these specific engineering requirements.

Design and Fabrication

Giant Inflatables Industrial designed a bespoke unit measuring 2.8 metres in diameter and 5 metres high. The unit weighs only 53 kg, making it easy to transport and deploy.

Key features include:

- High-strength 50mm webbing handles for positioning.

- Stainless steel D-rings for secure rigging.

- A quick-inflate valve system for rapid deployment.

- Working pressure capacity of 3psi or 20kPa.

The Debris Fall Protection Plug’s design allows operators to lower the uninflated tube into the stack using hanging ropes. Once in position, air pumps inflate the unit to create a tight friction seal against the stack walls.

Results

The High Impact Demolition Team lowered the Debris Fall Protection Plug into the target section and inflated it, stabilising the structure and enabling it to capture loose material if needed. Cranes then detached the stack section and lowered it to the ground without incident.

The client reported the system worked precisely as planned, and the Debris Fall Protection Plug allowed High Impact Solutions to complete the demolition phase safely.

Kind words

Dear David,

The team has started, and today was the day the first section came down utilising the balloon on the internals of the stack, which has worked perfectly with the pumps and done exactly what we envisioned.

Thank you for all your help with this. I really appreciate everything

Luke Cook

Demolition Manager, HISG

A closer look

Need information off-line?

Download a PDF for your records in two steps.

Need more information?

Contact us. We would love to be apart of your solution.