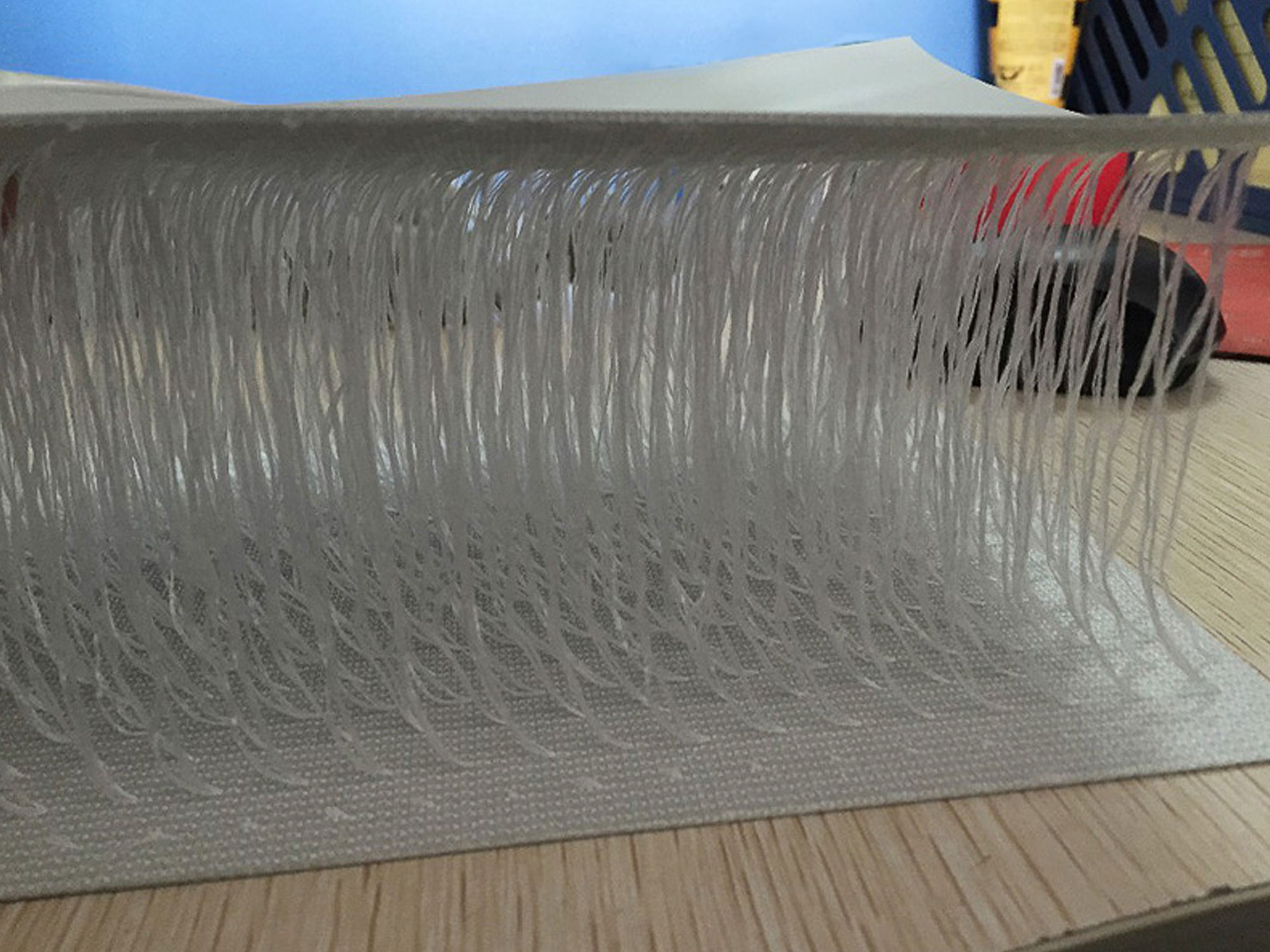

Drop stitch matrix web constructed inflatables

The drop stitch material used in Matrix Web-constructed inflatables facilitates the creation of inflatable structures with entirely flat surfaces, ensuring enhanced rigidity and stability. Constructed by intertwining thousands of fine polyester threads tightly between two external layers of material, this fabric, when inflated, tightens the threads, resulting in a robust surface.

Employing drop stitch matrix web construction techniques enables users to inflate products to higher pressures, creating a superior level of rigidity compared to standard inflatables. This characteristic makes it particularly suitable for a multitude of industrial uses.

Matrix Web-constructed inflatables utilise drop stitch material to achieve flat surfaces, enhancing rigidity and stability. This fabric, created by tightly intertwining fine polyester threads between two external layers, forms a robust surface when inflated. Employing drop stitch matrix web construction allows for higher inflation pressures, offering superior rigidity ideal for various industrial applications.

The adaptable nature of drop stitch, and matrix web-constructed inflatables makes them suitable for a wide range of industrial uses, offering stability and versatility in different settings.

Common Uses for Drop Stitch Matrix Web Constructed Inflatables

Compression Load Testing

Drop-stitch matrix web-constructed inflatables are often used when compression load testing products. In this context, these inflatables are strategically placed on, under, or around objects undergoing compression tests. When inflated, they create a controlled environment, facilitating precise testing conditions.

The drop-stitch matrix web construction ensures uniform pressure distribution, crucial for accurate and reliable compression test results. Their flexibility allows for customization, accommodating various shapes and sizes, offering a practical solution for industries that require meticulous testing of materials and structures under compression forces.

Formwork and Shuttering

Drop stitch matrix web-constructed inflatables serve as flexible forms in concrete construction, offering quick setup and removal for time-sensitive projects. Their adaptability to complex shapes, lightweight design, and easy storage make them efficient for diverse construction elements. The matrix web construction enhances rigidity during concrete placement, ensuring stability.

These inflatables are reusable, cost-effective, and suitable for curved surfaces. Additionally, they offer a more robust seal on uneven surfaces and ease of installation in intricate spaces.

Lifting Bags

Drop-stitch matrix web-constructed inflatable bags, employed as load testing bags, are versatile tools in diverse industries. Their controlled inflation allows for a gradual and even lift, ensuring the safe positioning of heavy loads without causing damage. They provide stability during the lifting process, minimizing the risk of load shifting or tilting, especially with irregularly shaped loads. Compact and portable, these bags are easily transported to different locations and installed in awkward places making them convenient for various lifting scenarios. The adjustable lift height feature adds flexibility, catering to a range of load sizes.

These bags are crucial in emergency response situations, ensuring a safe and controlled lifting operation.

Drop Stitch Matrix Web Constructed Decks

Drop stitch inflatables are ingeniously applied as decks, providing a reinforced and rigid surface for various activities. Known for their flexibility and strength, matrix web-constructed inflatables serve as resilient decks offering stability, comfort and safety.

By combining matrix web-constructed inflatables with other inflatable elements, such as floors, walls or barriers, a robust and adaptable environment is created. Moreover, they complement other inflatable applications, especially in scenarios demanding a sturdy platform over a void-forming inflatable.

Frequently Asked Questions

This advanced construction technique connects the top and bottom surfaces of the inflatable with thousands of fine internal threads. When inflated to high pressure, these threads pull taut, preventing the structure from rounding and creating remarkably flat, stable, and rigid surfaces.

Matrix web forms are lightweight, reusable, and significantly faster to set up and remove than traditional timber or steel formwork. Their ability to be made into complex shapes reduces labor costs and increases efficiency on site.

This technology allows for the fabrication of a wide variety of complex custom shapes. It is possible to engineer structures with sharp corners, true right angles, and precise curves that cannot be achieved with standard inflatable construction methods.

They are engineered to be inflated to very high pressures. This high internal pressure, combined with the internal matrix of threads, provides the exceptional rigidity needed to maintain a precise shape, even when under the significant hydrostatic load of wet concrete.

Their low weight and compact deflated size make them easy to transport and handle with minimal personnel. This significantly reduces project costs by lowering transportation expenses and the labor required for setup and removal.

Giant Inflatables Industrial builds these products from high-quality, durable materials designed for repeated industrial use. Should damage occur, it can typically be repaired on-site with specialised patching kits, ensuring a long and reliable service life.

Drop stitch matrix web cushion makes beach wheelchair more accessible.

The drop stitch matrix web lifting cushion makes getting in and out of the beach wheelchair easier and safer.

Using an Inflatable Matrix Web-Constructed Airbag for Pallet Testing

Giant Inflatables Industrial designs inflatable matrix web-constructed airbags to test the flexural stiffness and strength of a transport pallet.

Need more information?

Contact us. We would love to be apart of your solution.