Background

Alinta Energy

Loy Yang B Power Station

Alinta Energy is one of Australia’s largest energy retailers, generators and developers and owns and operates power stations across Australia and New Zealand. One of their Power Stations is the Loy Yang B Power Station, a brown coal-fired power station in Victoria’s Latrobe Valley, approximately 160 km east of Melbourne. Their two electricity-generating units supply approximately 20% of the power in Victoria, Australia.

Power generation companies strategically schedule maintenance during milder seasons, when electricity demand is at its lowest. In Australia, this occurs in Autumn, from March until May, and in spring, from September to November. This planning allows the power plants to be prepared for the peak energy usage of the coming summer and winter without disrupting the power supply.

The shutdown specialists at the Loy Yang B Power Station were preparing for the spring maintenance schedule. They were looking to make efficiencies in the maintenance program by identifying and rectifying various pain points throughout the blasting process.

Challenge

The spring and autumn shutdown seasons are particularly busy for all shutdown specialists in the Electric Power Generation Sector.

Traditionally, maintenance crews use scaffolding to create temporary blasting shelters to perform maintenance on significant components such as power turbines, valves, and transformers, which are often too large, too fragile, and too expensive to move off-site to be serviced.

Scaffolding, often used to build temporary blasting shelters, is a time-consuming and labour-intensive process that requires a significant amount of manpower working at unsafe heights for weeks to provide a temporary workshop for maintenance such as abrasive blasting, mechanical work and painting. Outdoors, temporary roofs on scaffolding are challenging to control in wind or rain conditions.

Additionally, the seasonal demand for scaffolding is high during these active maintenance seasons, and it is often necessary to book the assembly of scaffolding shelters up to three months in advance.

At a closer glance, the traditional scaffolding shelter, when considering rental costs, setup, and dismantling time, proved to be a costly and potentially inefficient method to provide a temporary blasting shelter.

Identifying the opportunity to increase efficiency and reduce costs during maintenance downtimes, the forward-thinking maintenance team at Loy Yang B Power Station contacted The Giant Inflatables Industrial Team to fabricate an inflatable industrial workshop that the maintenance crews could use indoors and out whenever and wherever they needed it.

The overall objective was to lower overall maintenance costs by minimising downtime and increasing productivity, all while enhancing the safety of the working environment.

Design

Results

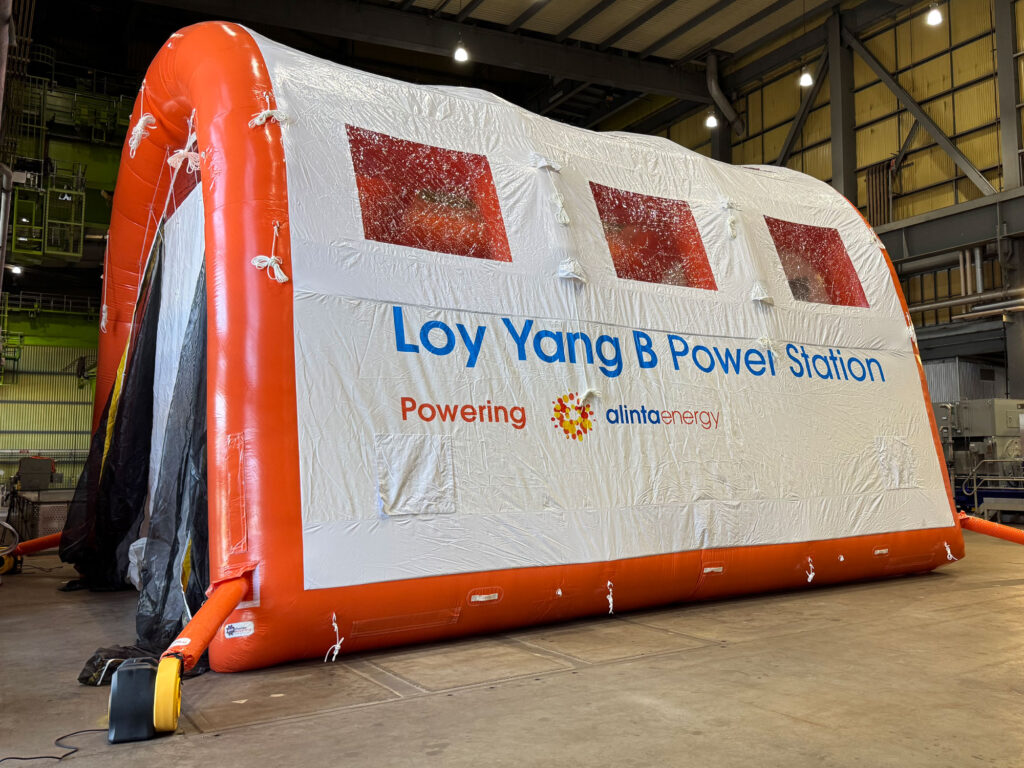

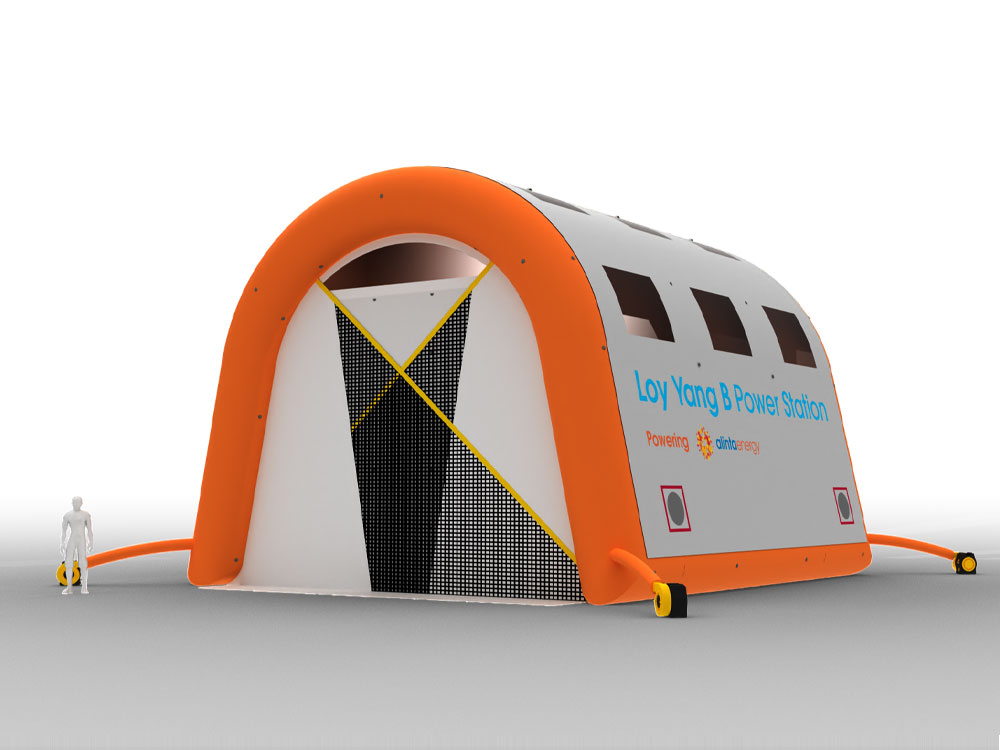

The inflatable blasting shelter, weighing around 500 kilograms, arrived on a single pallet in its specially designed ezy pack. For the initial deployment indoors, six people took approximately half an hour to unroll and inflate the inflatable workshop.

The inflatable workshop provides over 120 square metres of workspace with 7.5 metre-high ceilings, with a large entrance allowing the team to work on a variety of significant power components.

When the maintenance task is completed, deflating the unit and rolling it up to its original packing size takes around 45 minutes.

When not in use, the inflatable workshop is stored on a pallet, making it easy to store and deploy whenever and wherever it is needed at a moment’s notice. From a cost perspective, it is estimated that the one-time investment will be recovered within two maintenance cycles when compared to the cost of employing traditional temporary scaffolding workshops.

The inflatable workshop will provide the power generation plant with five to ten years of service.

A closer look

Need information off-line?

Download a PDF for your records in two steps.

Temporary Abrasive Blasting Shelter saves time and money

Origin Energy saves person-hours and creates a safer working environment with an inflatable temporary blasting shelter.

Portable Blasting Shelter for Siemens Australia

The Service Operation Team at Siemens approached Giant Inflatables Industrial to custom design a Portable Abrasive Blasting Shelter.

Need more information?

Contact us. We would love to be apart of your solution.