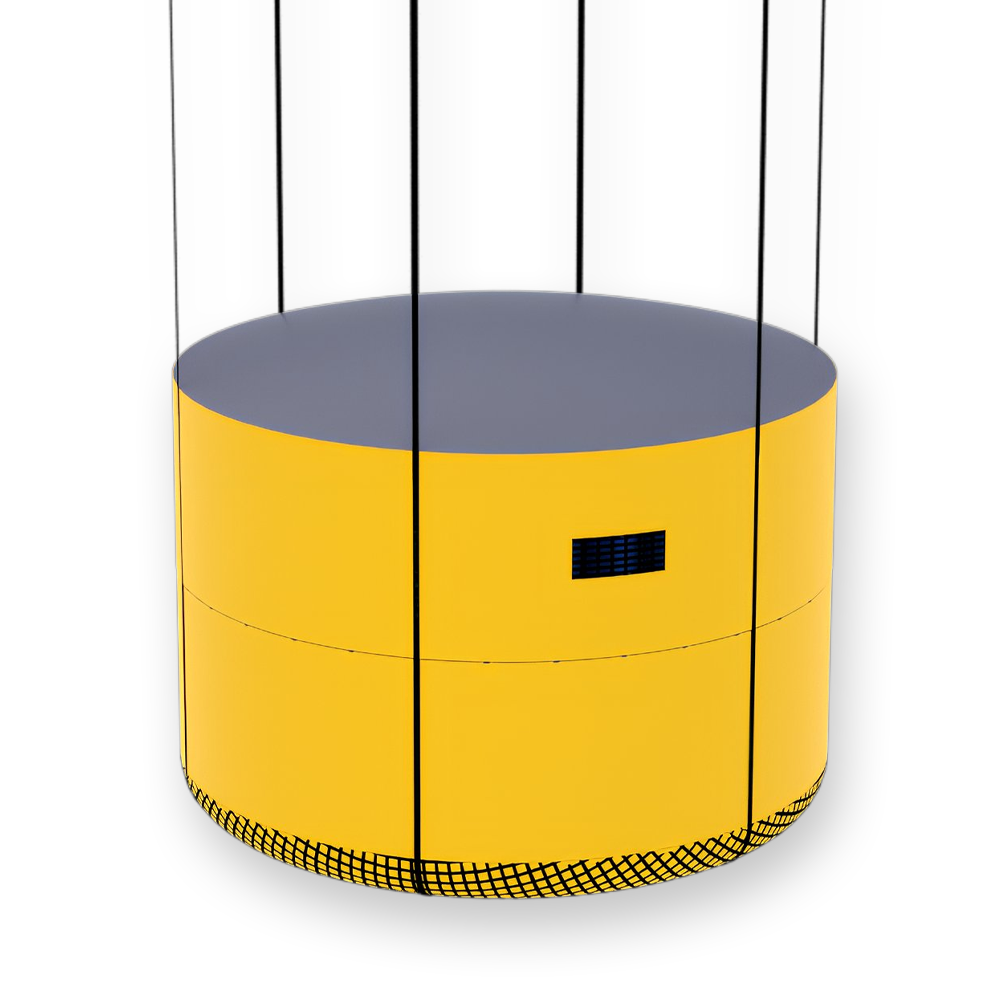

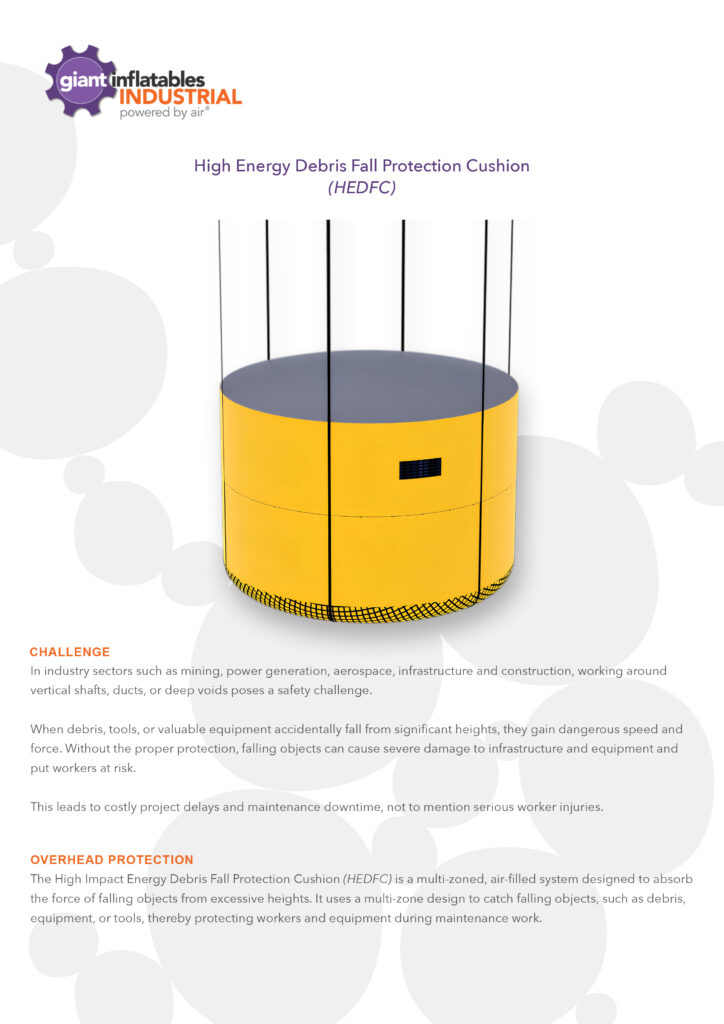

High Energy Debris Fall Protection Cushion

The High Impact Energy Debris Fall Protection Cushion (HEDFC) is a multi-zoned, air-filled system designed to absorb the force of falling objects from excessive heights. It uses a multi-zone design to catch falling objects, such as debris, equipment, or tools, thereby protecting workers and equipment during maintenance work.

the challenge

Falling Equipment, Objects and Debris

In industry sectors such as mining, power generation, aerospace, infrastructure and construction, working around vertical shafts, ducts, or deep voids poses a safety challenge.

When debris, tools, or valuable equipment accidentally fall from significant heights, they gain dangerous speed and force. Without proper protection, falling objects can cause severe damage to infrastructure and equipment and put workers at risk, leading to costly project delays and maintenance downtime, as well as serious worker injuries.

THE solutioN

High Energy Debris Fall Protection Cushion (HEDFC)

The High Impact Energy Debris Fall Protection Cushion (HEDFC) is a multi-zoned, airfilled system designed to absorb the force of falling objects from excessive heights. It uses a multi-zone design to catch falling objects, such as debris, equipment, or tools, thereby protecting workers and equipment during maintenance work.

A CLOSER LOOK

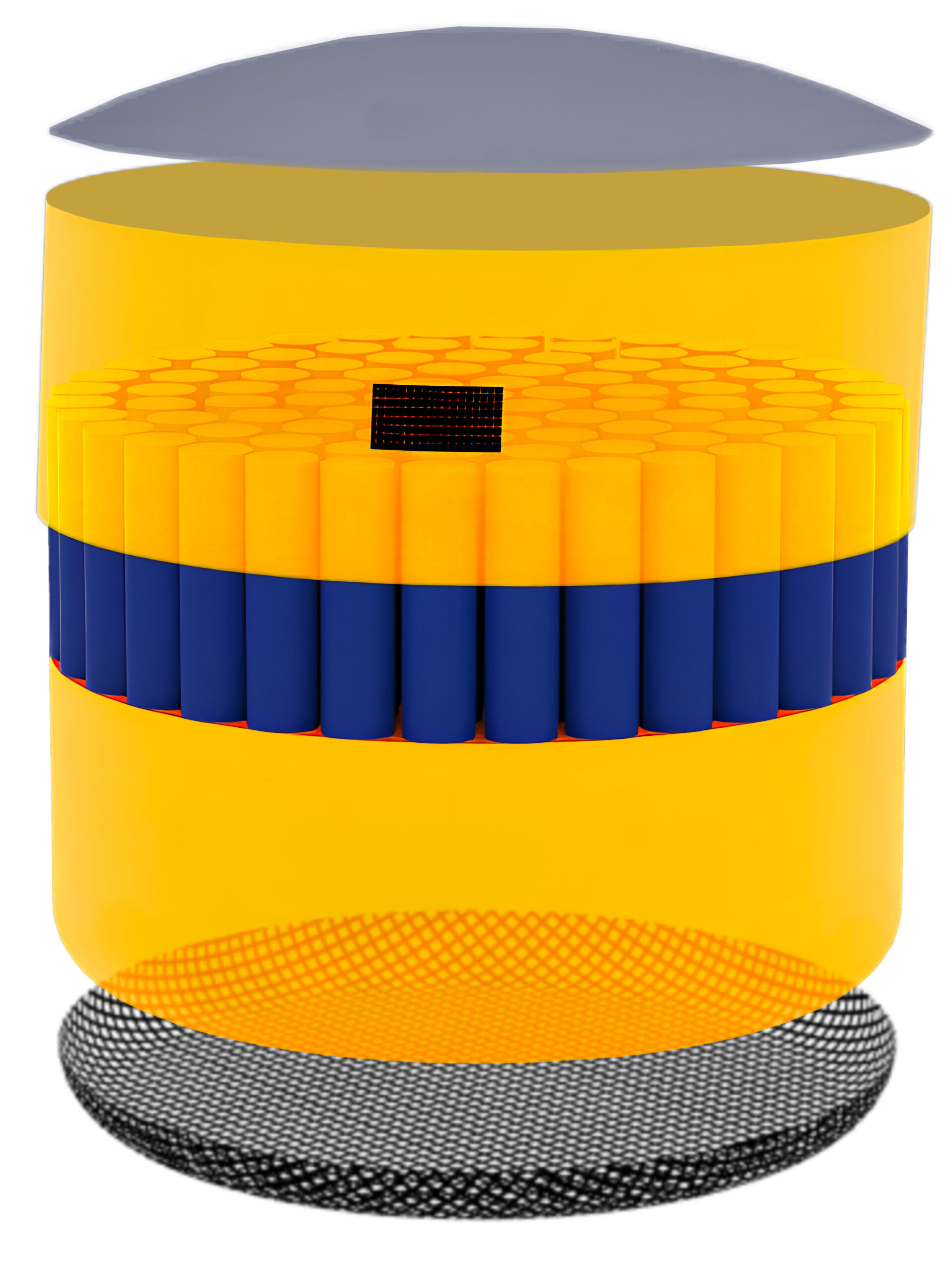

3 Impacts Absorption Zones

The High Energy Debris Fall Protection Cushion (HEDFC) system comprises three distinct areas, or zones, that work in concert to arrest

high-velocity impacts when they occur.

ZONE 1

Ballistic Cloth Membrane Impact Layer

Zone 1 comprises a primary air chamber covered with ballistic cloth, a high-strength,

technically woven fabric chosen for the ballistic properties that prevent it from being

pierced by objects during high-velocity events.

This layer is used to contain falling debris or objects and to absorb and diffuse the impact

force across the entire cushion in a controlled manner.

ZONE 2

Zone 2 comprises two interdependent parts: the main air chamber housing and an array of individually inflated shock absorbers.

Upper Compression Air Chamber

The chamber is constantly inflated to approximately 1.6 kPa. When the impact force is transferred from above, the compression air chamber, together with the shock-absorbing array, significantly reduces the falling velocity.

Array of Air-filled Support Shock Absorbers

Within the compression air chamber is an array of upright, air-filled supports that act as shock absorbers, allowing each support to compress independently to absorb impact pressure.

ZONE 3

Zone 3 is a shared air reservoir at the base of the system that dampens pressure changes.

A fan runs continuously to maintain a stable system pressure throughout the entire unit, replacing lost air through venting or minor leaks and restores readiness between impacts.

Ballistic Cloth Membrane Impact Layer

Air Chamber and Inflatable Shock Absorbers

All three zones of the High Energy Debris Fall Protection Cushion are encapsulated in a chamber that is continuously inflated to 1.6 kilopascals (1.6 kPa) and held together and suspended by high-strength webbing. Over-pressure vents are positioned on the side of the unit to prevent over-pressurisation.

REDUNDANCY PROTECTION

Debris and Equipment Containment

- Ballistic cloth cover

- Dynamic response zone cover sheet

- Individual shock absorbers

- Manifold reservoir cover sheet

- Bottom containment net

Impact Attenuation

- Cell 1: Air chamber

- Cell 2: Dynamic response columns

- Cell 3: Manifold Reservoir

SUMMARY

The multi-zoned High Energy Debris Fall Protection Cushion secures vertical work environments by arresting falling objects, debris and equipment during critical maintenance, preventing structural damage and worker injury.

Implementing this engineered barrier creates a safer workspace while protecting expensive infrastructure and equipment during essential maintenance operations.

Frequently Asked Questions

A High Energy Debris Fall Protection Cushion protects your worksite from falling objects. This multi-zoned system fills with air to absorb the force of debris falling from extreme heights. It shields workers and expensive equipment during maintenance in vertical shafts or deep voids.

- Zone 1 features a ballistic cloth membrane to capture debris and diffuse impact forces.

- Zone 2 contains an upper compression chamber and individual shock absorbers.

- Zone 3 acts as a shared air reservoir to dampen air pressure changes.

- The system maintains a constant pressure of 1.6 kilopascals to ensure readiness between impacts.

Your partner

in industrial inflatables

Need information off-line?

Download a PDF for your records in two steps.

Debris Fall Protection in Hydroelectric Power Plant in Nova Scotia

Debris Fall Protection is often needed in tunnel repairs caused by sinkholes in power plants, mines and infrastructure projects.

Inflatable Debris Fall Protection for a Major Austrian Mine

Wolfram Bergbau und Hütten AG faced a unique challenge-protecting workers from falling rock during essential maintenance in a deep, uniquely shaped mine chute with minimal access.

Equipment Fall Protection in the Aviation Sector

Equipment fall protection is essential in aviation to safeguard expensive equipment and parts during testing and maintenance.

Need more information?

Contact us. We would love to be apart of your solution.