Back Ground

EXPAC Australia

Australia-wide

The Lihir gold mine in Papua New Guinea is a large open-pit operation situated on Niolam Island, about 900 km northeast of Moresby, part of the Lihir Islands in New Ireland Province.

A launder is a vital piece of equipment used in ore processing. It is a trough, channel, or chute designed to transport slurry through different stages of the processing circuit, ultimately leading to gold extraction.

Occasionally, launders need maintenance to ensure the efficient flow of slurry.

Challenge

The Lihir gold mine, operated by Newmont Corporation in Papua New Guinea, faced a critical operational deadline. A primary ore-processing launder required essential resurfacing maintenance, and the project had to be completed before the onset of the region’s disruptive seasonal rains.

Traditional methods for isolating the maintenance area, such as installing fabricated steel plates, were deemed too time-consuming and would jeopardise the project schedule. A more efficient and rapidly deployable solution was required to mitigate the risk of weather-related production delays.

Custom Designed Solution

The custom-engineered inflatable bladder was delivered on schedule and performed to specification. The Lihir maintenance team was able to install the inflatable bladder significantly faster than traditional methods, establishing a safe and fully isolated work environment.

Results

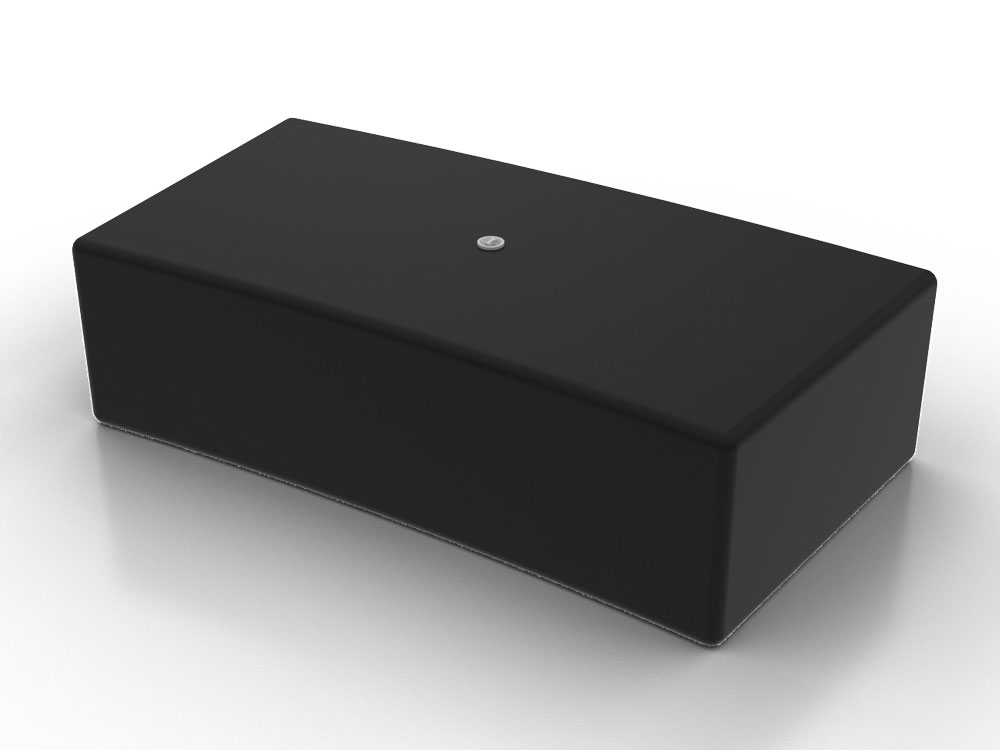

Procurement partner Expac Australia, acting on behalf of Newmont, engaged Giant Inflatables Industrial to engineer an inflatable bladder capable of providing a reliable, high-integrity seal within the launder.

The Giant Inflatables Industrial Engineering team initiated a collaborative process with project stakeholders.

This involved:

Technical Consultation: Defining the precise operational parameters, including the launder’s complex geometry and the hydrostatic pressures involved.

Rapid Prototyping: An iterative design and development process was used to produce and test several prototypes, ensuring the final design met the client’s exact requirements for fit and performance.

Advanced Materials: The inflatable bladder was constructed from a specialised composite material, selected for its durability and resistance.

A closer look

Need information off-line?

Download a PDF for your records in two steps.

Inflatable insulated isolation barriers

Inflatable insulated isolation barriers sequester specific areas and protect workers and the surrounding areas during maintenance and repairs.

Storm drain environmental protection system

A Storm Drain Environmental Protection System can prevent environmental damage caused by chemical spills leaking into the drainage systems.

Inflatable Duct Barrier for Critical Power Station Safety

The isolation duct cushion ensured that if there were any faults with the stack damper, the inflatable duct barrier would prevent downdrafts.

Need more information?

Contact us. We would love to be apart of your solution.